Blog Archives

Open Channel Flow – Manning Equation

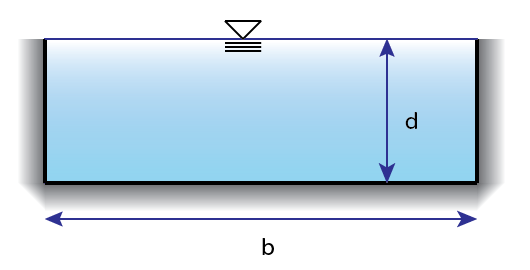

Manning’s Equation for open channel flow is the go-to equation for open channel problems. An open channel is basically anything that flows out in the open above ground as well as pipes that are not flowing to their full capacity.

$$ Q = \frac{1.49AR^{\frac{2}{3}}\sqrt{s}}{n} $$

Q is the flow and can be in either cubic feet per second (US) or cubic meters per second (SI). When using the equation for SI units leave out the 1.49 factor!

A is the Area of the channel. This can be determined with geometry for the easy rectangular and trapezoidal shapes or using table equations in combination with depth, base length, diameter etc. Find where channel geometry equations are in your reference.

Closed Conduit Hydraulics – Friction and Minor Losses

Friction and minor losses are glossed over in the darcy-weisbach article but I want to throw in some extra notes here. Friction occurs over every bit of length of a close-conduit system and is usually a surprisingly high amount of energy loss. Friction depends on the material of the pipe and the velocity of flow. The formula for frictional head loss IS the Darcy-Weisbach equation.

$$ h_f = f \frac{L}{D}\frac{V^2}{2g} $$

Closed Conduit Hydraulics – Hazen Williams Equation

Hazen-Williams can be used to determine the flow characteristics in closed conduits (pipe systems).

For Velocity

$$ V = 1.318CR^{0.63}S^{0.54} \text{ (US)}$$

$$ V = 0.849CR^{0.63}S^{0.54} \text{ (SI)}$$

S = slope, in decimal form. This is equivalent to \( h_f/L\)

R = hydraulic radius, \(\text{(Area of flow)}/\text{(wetted perimeter)}\)

C = Roughness Coefficient, get this from a table (available in both the AIO and CERM) Click here to continue reading

Closed Conduit Hydraulics – Darcy-Weisbach Equation

The Darcy-Weisbach equation is used to determine flow characteristics in closed conduit systems (pipes). It is probably more common than the Hazen-Williams equation due to it being able to solve for systems in both laminar AND turbulent flow.

$$ h_f = f \frac{L}{D} \frac{V^2}{2g} $$

- headloss \(h_f\) (ft)

- friction factor \(f\), length \(L\)

- length \(L\) (ft)

- diameter \(D\) (ft)

- velocity \(V\) $$\frac{ft}{s}\)

- gravity g \(32.2 \frac{ft}{s^2}\)

Friction Factor

The friction factor \(f$$ is either given or must be calculated using a Moody-Stanton diagram (available in both the AIO and CERM). Getting the friction factor from a Moody-Stanton chart requires the Reynolds Number \(Re\), and relative roughness \(\frac{\epsilon}{D}\). Click here to continue reading